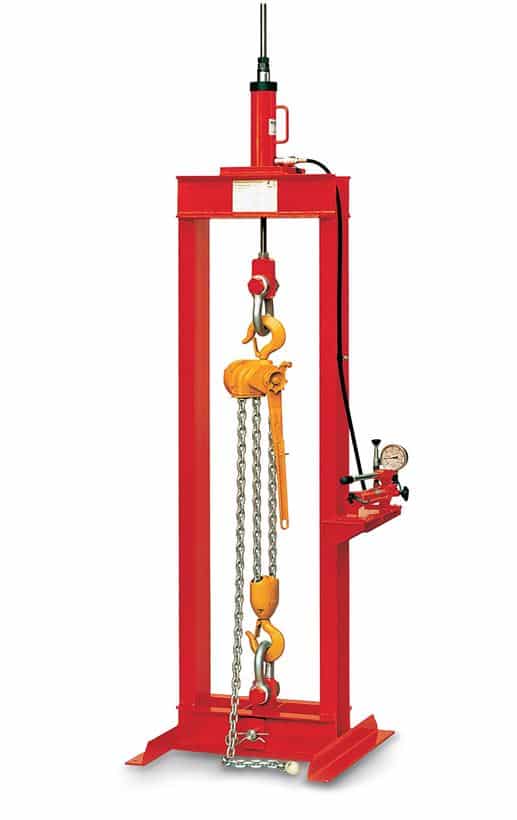

Description

For testing pul-lifts, lever hoists, chain blocks, wire rope pullers as well as other lifting equipment after repair or inspection.

Testing of hoisting equipment

The lifting unit is placed between upper and lower shackle, the chain is tensioned against the oil cushion of the partly advanced piston of the hydraulic cylinder. The applied force can be read at the pressure gauge.

Testing of the hoist brake

For a functional test of the hoist brake the hand pump may be used to apply a counter pressure and thus increase the pulling force after a general test.

Frequent use

For frequent testing, the hand pump may be replaced by a low-cost air hydraulic (model PAY-6) or electric pump (model PY-04/2/5/2 M.

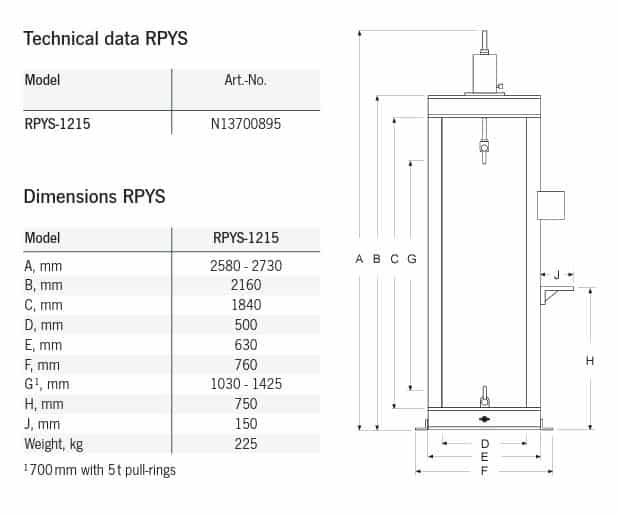

Pressure gauge

To read pulling forces more easily, the test rig is equipped with two high-quality pressure gauges.

Quick couplers allow an easy replacement of pressure gauges.

Pressure gauge 1 for small test items: GGY-1005, display: 0 – 160 bar, Ø 100 mm, Kl. 1.0 %%

Pressure gauge 2 for big test items: GGY-1003, display: 0 – 400 bar, Ø 100 mm, Kl. 1.0 %

AYP-1215-S Test plate for permanent load lifting magnets

Test load max. 12 t

For testing of permanent load lifting magnets according to DIN EN 13155

The plate is placed into the 12 ton test rig RPYS-1215 (or other versions of this test rig) and connected to the frame with a bolt.

The test plate with a standardised surface according to DIN EN 13155 kann be adjusted horizontally to align it steadily.

Dimensions: 800 x 490 x 60 mm

Features

• Fully welded, low-strain press-frame.

• Upper and lower hook suspension by means of shackles, incl. two 5 tons pull-rings for smaller test units.

• Lateral pump table.

• Infinite adjustment of the pulling force.

• Chart for easy determination of test force.

• Removable lower suspension e.g. for testing of plate clamps.

• Base pre-drilled for mounting.

• High-quality hydraulic components.

• YCS-21/150 hollow cylinder made from chromium-molybdenum steel, heat-treated and hard chromium-plated. Long cylinder stroke of 150 mm with bronze bearings.

• Two-stage quick action hand pump HPS-2/0,7A.

• High-strength threaded bar M27.

• Fine-adjustment pressure valve.