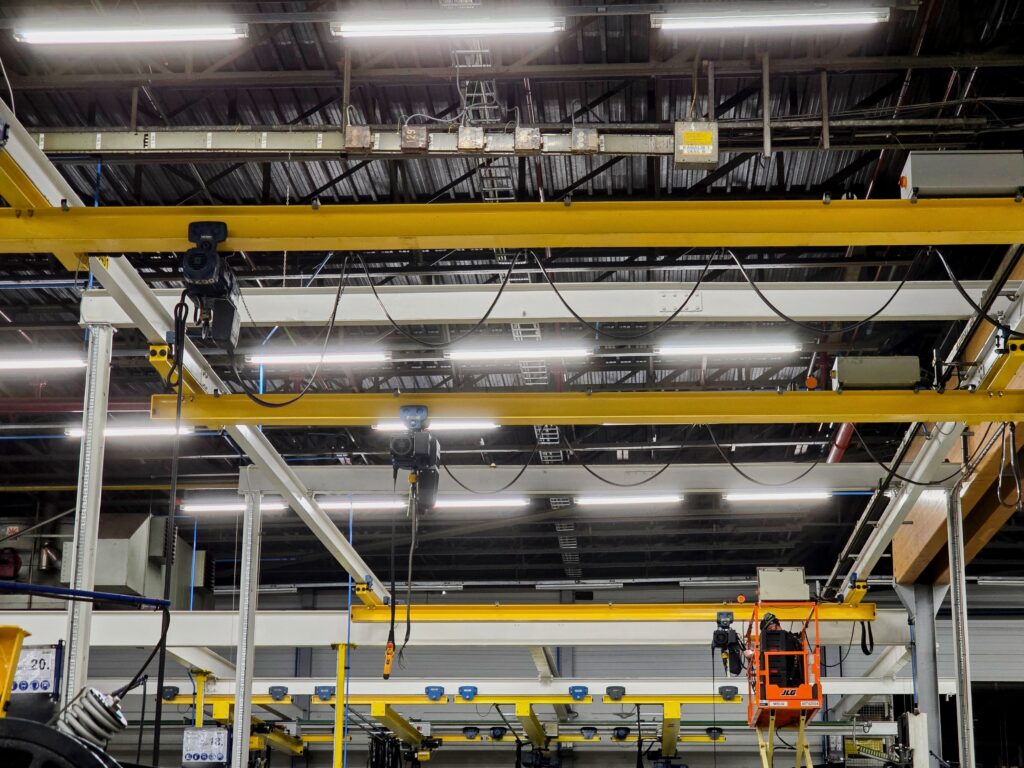

This summer, we carried out a major upgrade for a client in West Flanders: 12 electric chain hoists were replaced, not due to wear and tear, but as a clear choice for enhanced safety. The client wanted no more compromises and opted for a solution that minimizes the risks of traditional slip clutches.

🔧 Limitations of traditional slip clutches

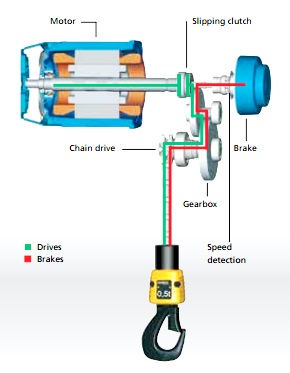

Many electric hoists are equipped with a slip clutch to protect against overload. While mechanically reliable, this system has several drawbacks:

- Imprecise adjustment: activation occurs between 130–160% of the nominal load.

- Wear sensitivity: temperature, humidity, and usage intensity affect the actual disengagement point.

- Risk of unintended load descent: since the clutch is often placed between the brake and the chain drive, prolonged slipping can lead to uncontrolled lowering.

🛡️ A safer alternative: clutch monitored by encoder

We implemented an advanced solution:

- The slip clutch is monitored by an encoder. When slip is detected, the brake engages immediately.

- The brake is mounted directly on the chain drive, separate from the clutch.

- The clutch is only between the motor and the drive, ensuring the load cannot descend uncontrollably.

👷♂️ Investing in safety

This decision reflects a clear vision: safe working is a priority. The system adds an active safety layer that can make a critical difference.

📞 Questions? Contact OHIS Industrie

If you have questions about safe lifting solutions or want to know what we can do for your company, feel free to contact our team at OHIS Industrie. We’re happy to help you find the most reliable and secure solution for your needs.