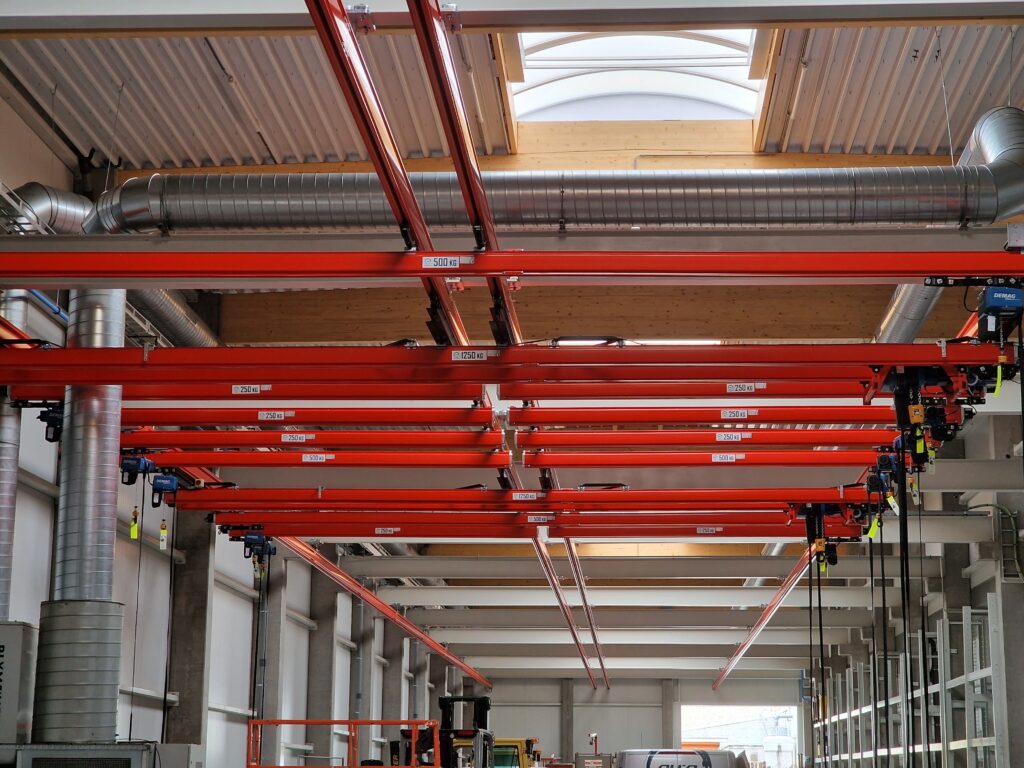

An efficient, well-organised overhead crane system is essential for modern industry and production facilities. In this article, we’ll look in detail at the installation of a new KBK crane system with 14 overhead travelling cranes. This system promises to improve operational efficiency and increase productivity in an industrial environment.

This summer, we had the privilege of supplying and installing a suspension crane system comprising 14 overhead travelling cranes in Zedelgem.

Planning and design:

Before installation actually begins, a thorough planning and design phase is essential. Engineers and specialists analyse the customer’s needs, the available space and the specific requirements of the crane system. This includes determining the optimum position of the overhead travelling cranes, the load capacity of each component and safety considerations.

Preparing the installation site :

Prior to installation, the installation site must be prepared. This may involve modifying existing structures or building new support structures to safely support the overhead cranes. It may be necessary to reinforce the ground so that it can support the load of the overhead cranes.

Assembly of overhead cranes :

The overhead crane assembly process begins. Each component of the KBK suspension crane system is carefully assembled according to the manufacturer’s specifications. This includes the installation of catwalks, overhead travelling cranes, hoists, slides and other relevant components.

Electrical and mechanical connections

Once the cranes have been assembled, the electrical and mechanical connections are made. The electrical wiring is connected to the control panels and motors. It is of the utmost importance that all connections are made safely and in accordance with current standards, to ensure the correct operation and safety of the crane system.

Inspection before commissioning

Before being put into service, the KBK suspension crane system undergoes a full inspection by an independent testing body. This includes testing the overload protection devices using test weights and checking that the system operates correctly at the rated load. Any faults or problems are identified and resolved to ensure that the system operates at optimum efficiency.

The installation of the Demag KBK suspension crane system with 14 overhead travelling cranes by OHIS Industrie is an inspiring example of technological progress and cooperation in the industrial sector. Thanks to precise planning, high-quality manufacturing, flawless installation and extensive training, OHIS Industrie has made a tangible difference to the production capacity and efficiency of the company concerned. This project underlines the importance of innovative solutions and partnerships in creating a modern and efficient production environment.